PURSUE SP9000 LAMINATING PROCESS CERTIFICATION

SP9000 Laminating Process Certification is a United States Federal Government registered manufacturer prequalification practice performed by the Fiberglass Reinforced Plastics Institute (FRPI) once upon initial certification and then annually for renewal. It is a minimum manufacturer expertise “proving ground” type program similar to that provided by Air Movement Control Association for fiberglass fan and damper performance rating plus Underwriters Laboratories and Factory Mutual for fiberglass ductwork fire ratings. FRPI certification is not a standard that a manufacturer complies with, but rather a rating process to benchmark their capabilities against FRPI minimum requirements.

Capabilities differ widely between manufacturers. A fiberglass industry study conducted found that 79% of 754 causes of failure reported involved issues that are significantly influenced by the Manufacturer. Ongoing field inspection frustratingly confirms similar findings year after year following the study. Laminating Process Certification recognizes well-qualified Manufacturers and publicly lists them for specifier reference in an effort to help eliminate risks associated with manufacturer performance for the betterment of business and safety conditions.

FRPI SP9000 Laminating Process Certification is the first part of a two part process for Equipment Certification. The second part is FRPI SP9100 Laminate Certification. When used together, these two (2) certification processes enable specifying engineers to obtain low-risk equipment from well-qualified manufacturers on a competitive level playing field. SP9000 is an annual FRPI certification process that qualifies manufacturers, whereas SP9100 is a certification process performed by FRPI on a job-by-job basis qualifying equipment manufactured and shipped. These standard practices are included in the Laminate Certification manual.

FRPI performs objective audits of the manufacturer’s laminating processes per SP9000, with the intent of issuing a Laminating Process Certification. This audit is performed for a fee by FRPI at the request of an authorized manufacturer’s employee. The fee is payable to FRPI by the candidate manufacturer who desires to operate an FRPI Certified Laminating Process. The audit includes a quantitative and qualitative review of capabilities that are associated with:

- General Facilities

- Application Diversity

- Engineering

- Standards and Specs

- Submittal Preparation

- Layout

- Resin Formulation

- Reinforcement Processing

- Permanent Molds / Tooling

- Mold Building

- Laminating Methods

- Demolding

- Machining

- Assembly and Fabrication

- Secondary Bonding

- Finishing

- Post-Cure Methods

- FDA Prep Procedures

- Performance Testing

- Handling and Packaging

- Field Operations

- QA / QC Implementation

- Safety

- Environmental Compliance

- Customer Support

- Industry Development

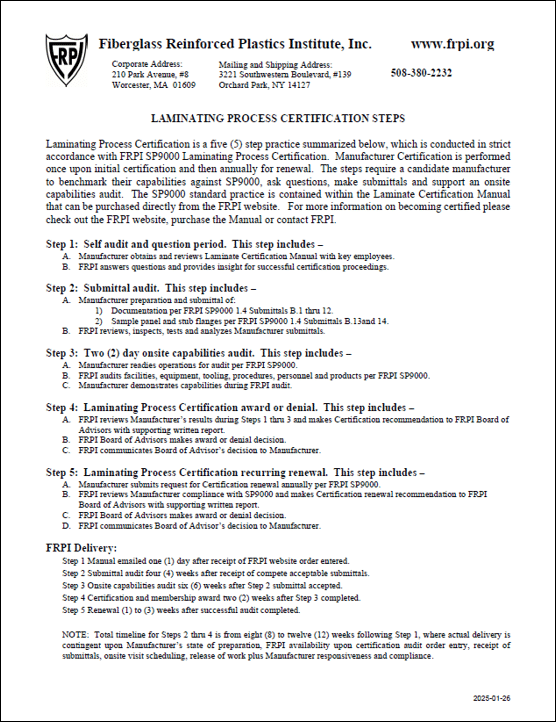

SP9000 Laminating Process Certification is accomplished following a five (5) step practice. This practice facilitates review of the areas listed above, which includes: a sample engineering submittal following FRPI SP9100 inspection, testing and analysis of sample laminates and stub flanges; onsite auditing of operations and inspection of in process laminating, fabricating and secondary bonding activity plus testing the knowledge level of engineering and production leaders. Laminating processes covered by the audit as a minimum are hand lay-up, spray-up and filament winding, which are the primary processes utilized in the manufacture of custom FRP process equipment.

In order for a manufacturer to receive a Laminating Process Certification following the audit they shall demonstrate to FRPI that they have had the capability, for greater than five (5) years, to produce laminates that consistently meet the intent of published FRPI standard practice for Laminating Process Certification. Upon successful completion of the audit process, the manufacturer is awarded a FRPI Certified Laminating Process certificate bearing a certification number for traceability purposes. For more information on becoming certified, please click the Laminate Certification manual or contact FRPI.

Manufacturers holding a valid FRPI Laminating Process Certificate for providing certified equipment are accountable for maintaining their capabilities demonstrated and producing equipment that meets plans and specifications on a job-by-job bases. Failure to meet these requirements when representing their work as an operator of an FRPI certified laminating process may be grounds for warnings or immediate Laminating Process suspension or termination following SP9000 procedures. Manufacturer accountability is upheld through annual Laminating Process Certification renewal, potential annual unannounced FRPI shop audits and Laminate Certification performed on candidate equipment certification projects submitted from time to time.

Anyone detecting an incident involving a manufacturer holding a valid FRPI Laminating Process Certificate whereby they deviate from FRPI standard practices, laminate specifications, specification bulletins, plans and/or equipment specifications referenced in a contract requiring FRPI equipment certification is eligible and encouraged to report it. Reports shall be filed by Owners, Owner’s Agents, Engineers, and/or Intermediaries through the incidents reporting process available on the FRPI website. Action against such reports shall follow SP9000 procedures.