PURSUE SP9000/SP9100 EQUIPMENT CERTIFICATION

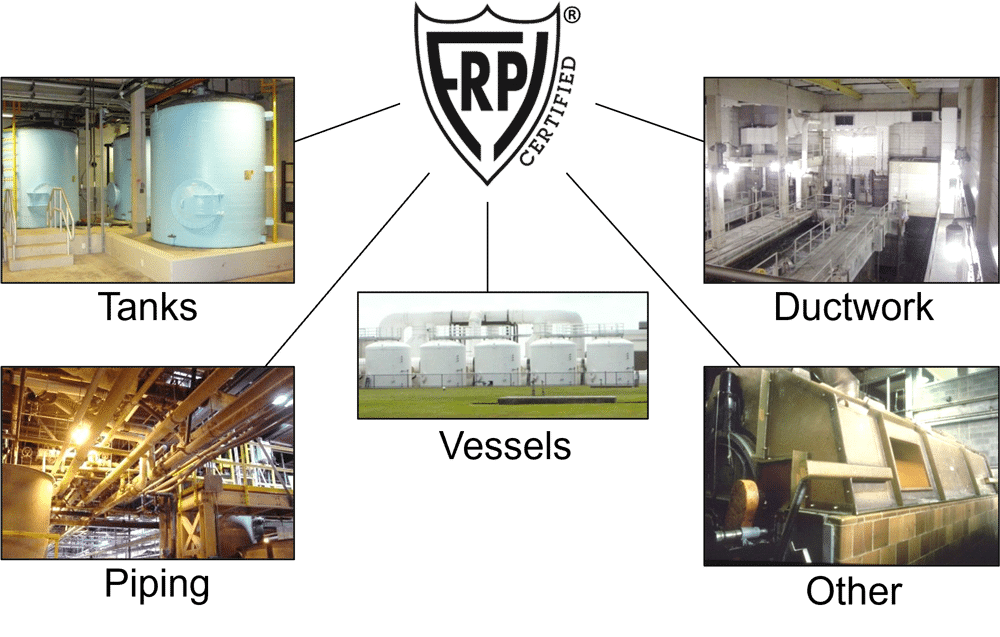

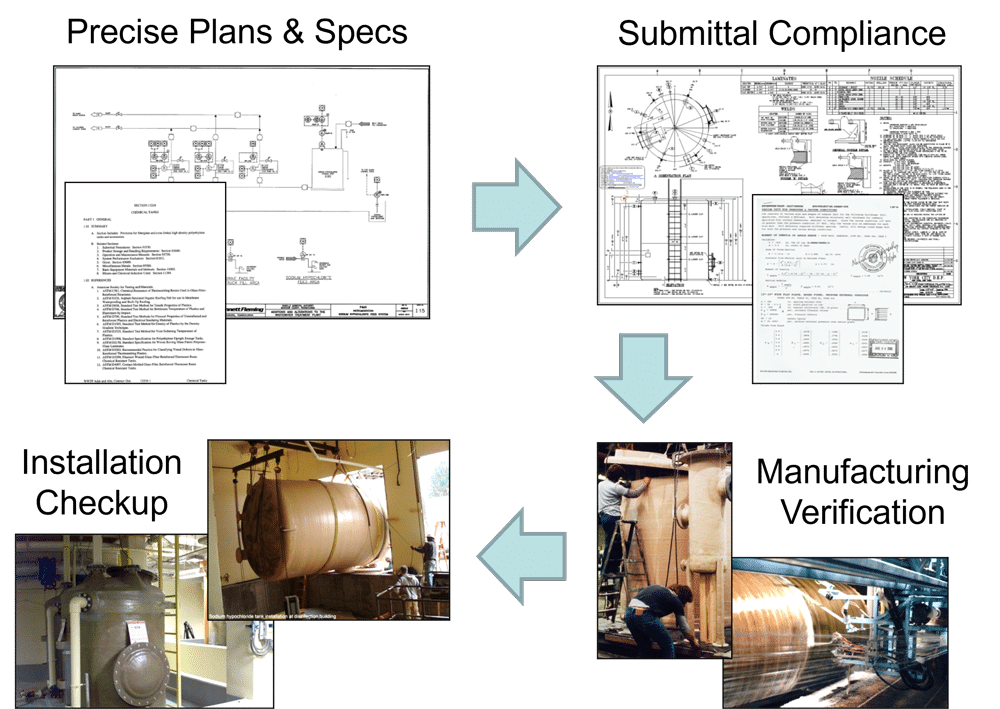

The Fiberglass Reinforced Plastics Institute (FRPI) performs a four (4) step equipment certification process that assists specifying engineers with obtaining low-risk equipment on a competitive level playing field. Over fifty (50) areas of potential risk are assessed by the process. Certification includes manufacturer prequalification per FRPI SP9000 Laminating Process Certification, with auditing of submittals, manufacturing, and installation activities on a job-by-job basis per FRPI SP9100 Laminate Certification.

Longer Life • Reduced Cost • Hardship Prevention • Improved Inspection

Four (4) step process utilizes

Certified Manufacturers

Equipment Certification is a cost-effective subset of FRPI Services performed during the design and construction phase of your projects. Certification puts risk management on “Autopilot” for your project and company locations across North America when properly incorporated into project and master specifications. Assistance with developing precise plans and project or master specifications is also provided to help better manage risk.

Equipment Certification is governed by standard practices, specifications and bulletins published in the FRPI Laminate Certification Manual. This Manual is a “Reviewed” document, which was initially accepted by FRPI’s Board of Advisors on November 21, 2005. The Board was staffed at that time by a balanced industry group of seven (7) professional engineers, one (1) of which is a past Chairman of the ASME RTP-1 committee for nine (9) years. The initial document was called the 2004 Edition. Industry and the general public are invited to contact FRPI and comment on the Certification process controlled by the Manual. All comments will be taken into consideration by the Board for future editions of the Manual.

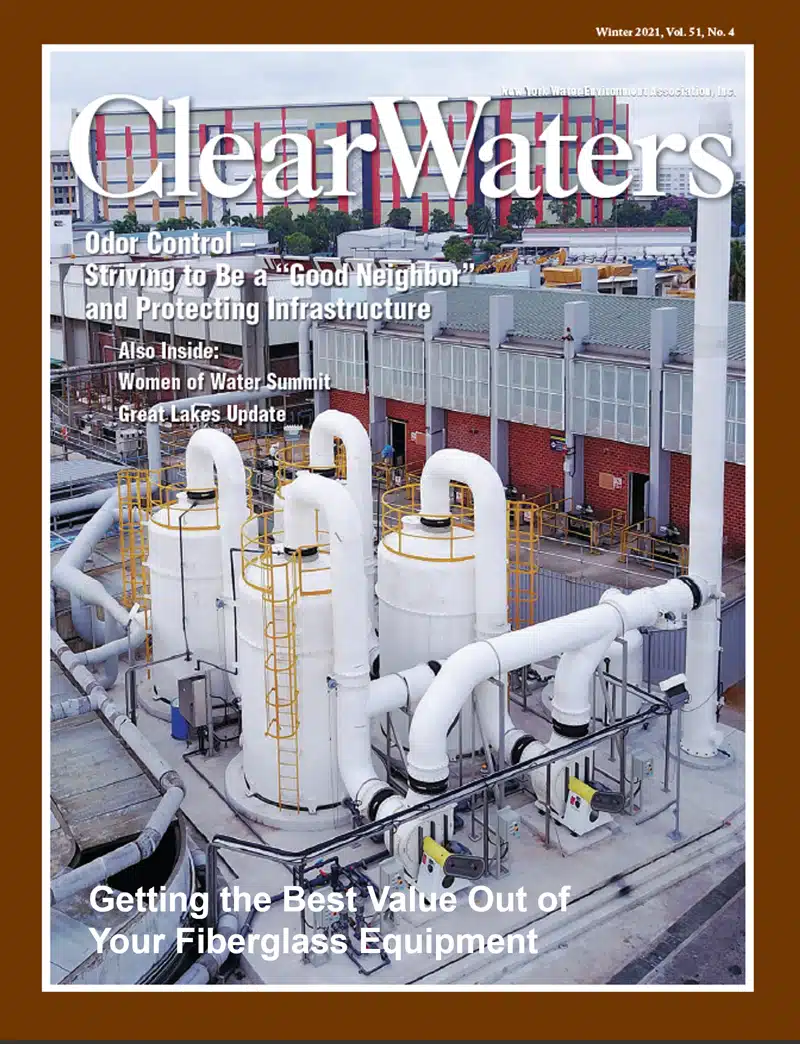

Industry failure analysis experts estimate that approximately a third of all fiberglass equipment in demanding service does not fulfill its initial design life without significant future investment in repair or replacement. Corrective action has demonstrated total owning and operating costs are lower when equipment is properly engineered, manufactured and installed. This high rate of failure has been proven to stem from a combination of the following circumstances:

- Highly fragmented supplier base

- Very price-sensitive market

- Poor specifications

- Unqualified manufacturers

- Inadequate technical proposal review

- Deficient engineering submittal review

- Limited to no manufacturing surveillance

- Improper installations

Ask the Experts! Contact FRPI now to learn more about how Certification manages risk for you and your company.